UPDATE: Laws regarding Hemp production in the United States have changed drastically since this article was originally written. Many states have legalized Cannabis in both the hemp form and the marijuana form, making hemp more readily available here in the US. Click Here for a site about the legalization of hemp.

Eco-friendly fibers mean more than a label. In this modern age of technology and quick results, there are always a few people who are keeping alive the old ways of doing things. Maybe it’s a hobby, maybe it’s a passion, or maybe it’s a family tradition, but they learn and carry on a slower way of producing. Many are organic, but all of them take more time and care to create products with less impact on the environment. There are communities of handspinners all over the world, making natural fiber yarn from raw materials. Small, sustainable farms and ranches are providing a lot of the eco-friendly fibers that create handspun slow yarn.

If you’d like to learn more about the sustainability of man-made “natural fibers,” you may be interested in reading https://slowyarn.com/rayon-ingeo-soy-silk-bamboo-and-more/.

WOOL

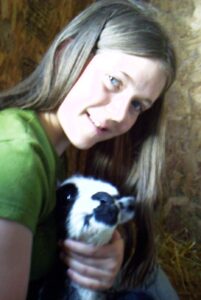

One of the most popular fiber for handspinning is wool. Often a family operation, raising sheep for the handspinners market involves a close relationship with the animals that are producing wool.

This Polypay cross ewe just had spotted twin lambs. Notice her jacket, keeping her full fleece clean. This is the kind of care taken by sheep producers who are focusing on the Slow Yarn market.

When sheep are raised in a handspinner’s flock they often have names and are kept more like pets than like livestock. Great care is taken by their owners to provide quality care based on the individual needs of each sheep. Colored fleeces have been bred out of large commercial sheep operations for hundreds of years. It is a modern innovation to begin breeding sheep specifically for their beautiful, naturally colored wool again. This breeding has been fueled solely by the slow yarn movement, and colored sheep fleece is in high demand with handspinners across the globe.

Did you know that the term “black sheep of family” refers to the practice of culling any sheep with colored fleece? This is because white wool takes a dye more brilliantly, which traditionally meant the wool had a higher value. The modern eye, however, finds great appeal in the rich muted natural tones of grey, brown, or black wool. Handspinner’s flocks frequently breed for color, rather than for white.

Wool is a type of protein fiber. Because of characteristics of the individual fibers of wool, it is prone to grab together, or felt. In fact, wool felts better than any other protein fiber. This is both a good trait and a bad trait. Not so great if you toss your sweater in the machine washer and it comes out half sized, but a wonderful thing if you want a durable, compact surface on a blanket or a tote bag, boot linings, or any number of other products made from wool felt.

Handmade felt from wool has become a medium for fine art in recent years, as well. The qualities that make wool bond together as felt make it ideal for sculpture, as well as for two-dimensional painterly art. Wearable art showcases wool, and some large installation sculptures use wool felt as the medium.

You may be interested in reading about wool in regards to animal cruelty questions at https://slowyarn.com/what-can-vegans-wear-vegans-and-wool//

MOHAIR

Mohair is from the Angora Goat. People unfamiliar with Angoras might wonder why “that sheep with the horns is so skinny.” These amazing creatures produce two long, lustrous fleeces per year, compared to just one from sheep. Also bred for many ages to be pure white, the colored Angora is making a comeback within spinner’s flocks.

Kid mohair is the finest angora fleece, from the first two shearings of a young goat. Its softness, combined with the natural shine and durability the fiber is known for, makes beautiful fabric for clothing, characterized by a soft halo. As the goat gets older, mohair gets coarser and is more appropriate for upholstery fabrics or rugs. Mohair’s durability and fire resistance make it the fiber of choice

for car interiors, including race cars. Just like sheep, the Angora goat is a common member of the spinner’s flock. These hardy little animals are much more docile than most goat breeds, do not climb, and the males smell a whole lot less, too. They have charming personalities and have been part of the family flock living in close proximity to people since before Biblical times. In fact, the “flocks” mentioned in the Bible were probably Angora goats, not sheep. Now, they are a vital part of the Slow Life Movement, as they are very productive and easy to keep.

It isn’t just ranchers producing fiber for Slow Yarn. Farmers are busy all over the world producing organic cotton.

Because standard growing practices for cotton involve an appalling amount of chemicals, buying organic cotton is a great way to use your pocketbook to make a real difference in the environment,

Cotton, like wool and mohair, has been selectively bred for centuries, aiming for a pure white. But, cotton also comes in natural colors! Tans, golds, greens, and browns are all on the natural cotton palette. Handspinners have a variety of colored cottons to spin, and green-minded customers can buy ready-made products in organic cotton.

OTHER ECO-FRIENDLY FIBERS

There are a number of other fibers used in handspinning. They are less common, and it is a little more difficult to categorize them as eco-friendly. Silk, for instance, is rarely a locally grown fiber– at least in the US, even if the yarn made from it is handmade. Hemp or linen are both “bast” fibers, which undergo a retting process that requires a lot of water. Bamboo or rayon are both made through a fairly complicated commercial process that isn’t always great for the

environment.

Other protein fibers don’t felt as readily as wool, but make beautiful yarn. Alpaca is soft and elegant, and its cousin Llama can be just as soft when processed correctly. And there is nothing softer than cashmere. Angora, dog wool, camel down, and muskox are also luxury fibers that can be spun by the handspinner.

THE BAST FIBERS

These are cellulose fibers, from plant sources, which come from the woody stem of certain plants. The hair-like fibers are detached from the foamy core of the plant, separated from each other, and spun into a strong, mildew resistant thread.

LINEN

Linen is made from the flax plant, which is one of the most useful plants known to man. Linum usitatissimum has been the source of seeds for food, oil for cooking, sealing wood, repairing ships, and making the original version of linoleum flooring when mixed with cork, as well as making the thread which created everything from sails for Viking ships to sheets, towels, and other “linens.” Probably the origin of the Rumplestiltskin story, rough straw-like stems from the flax plant were quite literally “spun into gold.” Freshly spun flax makes a thread that is shiny and golden in color, and its value in the history of mankind is immeasurable.

Linen has been around for a long, long time. Not too long ago scientists made a discovery in Georgia, in Eurasia. In a cave, they found linen fibers dated around 36,000 years ago. To read more about this find and about the complicated processes demonstrated there, read https://slowyarn.com/dzudzuana-cave/. These fibers showed evidence of having been twisted and were died in a variety of colors including black, gray, turquoise and pink. This discovery shows a level of technological thinking that is astounding. Those colors are not all easy ones to create using natural dye methods. And the amount of time, work, and innovation necessary to process linen speaks volumes.

Linen is a “bast” fiber, which means it is a fiber from the stem of the plant. The plants are first “threshed, or combed to remove the useful seeds. Then each stem undergoes a process of “retting” (which, frankly, is a fiber person’s technical term for “rotting”), which loosens the fibers from the bark-like outer layer of the stem. After the retting has softened the fibers and loosened them from each other, the stem is pounded. The old-fashioned method was a bench-like tool called a flax-brake, with a long bar that was raised and dropped on the stems to further break apart the pieces of the stem. Next, the stems were “skutched.” This involved a more hands-on pounding of the fibers, softening it and finishing the separating of individual strands. The fibers were then combed through a tool with a series of nail-shaped teeth, called a hackle, ripping them apart. This also separated any shorter, weaker fibers and left a long “strick”– a continuous rope of fibers which could be wound around the distaff of a spinning wheel so thread could be pulled from it and spun.

For a really great page on flax and linen, visit the Farm at Coventry Flax tale. http://farmatcoventry.blogspot.com/2010/01/spinning-flax-tale.html

HEMP

This amazing fiber comes from the stem of the Cannabis Sativa L plant. In fact, the word “cannabis” is the origin of the word “canvas.” This is the same plant as marijuana but has virtually none of the chemical THC present. The two varieties were bred for vastly different purposes. At this time there seems to be a shift in the way this plant is viewed, and it may be legalized in the United States again in the near future. For some reason, the government was unable to make the distinction between banning a drug (THC) and banning a harmless and very beneficial plant fiber. Hemp was a major crop in the colonial period of the United States, and George Washington is generally said to have grown it on his estates.

Hemp, like linen, is a bast fiber. The material made from hemp fibers is durable, softens with age to make a very pleasant fabric for linens or clothing, is mold and rot resistant, and takes dyes nicely. Previously, all hemp had to be imported into the United States from other countries where it is legal to grow the plant, but laws are changing quickly in this regard.

RAMIE or NETTLE

Ramie is a variety of nettle, from the Urticaceae plant. It is another bast fiber source, with stems produced in the same way as hemp or linen. Ramie is an ancient fiber, used for many of the Egyptian mummy wrappings. It is a lustrous fiber, with an elegant drape to fabric woven from it.

OTHER PROTEIN FIBERS

SILK

Silk is a protein fiber, but very different than any of the others. It is lustrous and smooth, with no scales at all like those that help wool to felt.

It is a monofilament– a single continuous thread– that is created by a silkworm to make its cocoon. When used as a fiber, each cocoon may be either cut open or unraveled in a single thread. It is boiled to remove the sericin, which is a glue-like substance that held the threads together for the cocoon. The worm inside, unfortunately, won’t ever become a silk moth since it dies in the process of extracting the silk.

CASHMERE

Cashmere is another fiber from a variety of goat. Cashmere goats don’t have any of the curl of the Angora, and at first appearance, look quite coarse. The outer guard hairs you see, however, are not the fibers that make luscious, soft as a dream cashmere clothing. Cashmere comes from the undercoat, combed out and separated from any guard hairs that came out with the combing.

ALPACA

One of the camelid family originating in South America, the alpaca has become a favorite of home farms and ranches in the United States. Luscious, buttery soft wool has black, white, rose-grey or rich red-brown natural tones, making alpaca a sought-after luxury. Mixed with sheep wool it reduces the itchiness and adds red tones that are rare in colored sheep. The white takes dye color beautifully. Alpaca can be felted, but not as readily as sheep wool.

LLAMA

Alpaca’s cousin the llama also originates from South America. These beautiful camelids have a natural grace and strong personalities, which make them welcome on farms and ranches. Their wool consists of a guard coat and an undercoat. The undercoat is generally as soft as alpaca, as long as all guard hairs are removed before spinning. The guard hairs are a strong, durable fiber suitable for rope, rugs, or any end product that is not worn next to the skin. Llama comes in the same range of natural colors as Alpaca, and also can be dyed.

The llama also has another use around the ranch. They are natural guard animals, with a strong aversion to dogs and a sense of protection toward smaller members of their flock. A single llama is often used as a guard with a flock of sheep or goats out to pasture. Their size, just smaller than a horse, is intimidating to predators and they are fairly effective in preventing loss of smaller livestock.

CAMEL DOWN

Generally not grown as a ranch product in the United States, camel down still deserves a place on any list of luxury handspinning fibers. This wool comes in just one color- “camel,” but it can be dyed. Soft and buttery in texture, but very matte, camel down is often blended with silk to add luster without compromising its softness.

CHIENGORA

This fancy French word simply means “dog wool.” Many common varieties of dog have a soft fuzzy undercoat which is suitable for spinning into luxury yarn. It maintains a “halo” of fuzz around it after being spun, similar to mohair or angora rabbit. Once knitted or woven, the halo covers the fabric surface. It is a fine alternative to faux fur or real fur as it is a natural fiber but no animal was harmed for the product. In fact, healthier happier dogs will produce better wool! Chiengora is rarely used as a commercially produced fiber, but occasionally a designer will commission some specialty pieces utilizing it. Chiengora can be very hot when used by itself, so it is best mixed with sheep’s wool. Wool adds durability, elasticity, and breathability to dog wool fabric.

Occasionally people with a strong sense of smell complain that chiengora never loses its doggy odor, but I have found that a good washing removes any trace of the original wearer. When wet, it can smell a little funny, but any fiber smells different and stronger when wet.

ANGORA

Not to be confused with mohair, which is from the Angora Goat, angora comes from the Angora Rabbit. These beautiful creatures have been bred for long, luxurious wool. Knitted, felted, crocheted or woven, angora always has a dreamy softness with a cloudlike halo. Used alone, it is almost unbearably hot. It is many times warmer than sheep wool in spite of its light airy appearance. It is commonly mixed with wool and silk in commercial knits, resulting in a soft, luxurious knit fabric that is warm and elegant.

QUIVIUT

The wool of the muskox, called qiviut by the Inuit people who raise this luxury fiber in the far north of North America. Amazingly light and airy, Quiviut products are warm, soft, and beautiful. Because the muskox only really thrives in very cold areas, there are limited areas where they can live. This fiber is very, very expensive, but well worth the cost for a luxury item of clothing.

RAYON

Rayon is a fiber that is unique in that it’s manmade but not synthetic. Generally made from broken down wood pulp fiber that is extruded into a monofilament, this cellulose fiber has very similar properties to silk. It takes dyes beautifully, drapes elegantly, and feels soft to the touch. Unfortunately, it isn’t really an eco-friendly fiber. The process to make it requires several types of chemicals and a great deal of water, and disposal of the chemicals is an issue.

Newer types of fiber are produced in the same way as rayon but are made with bamboo fiber, corn cellulose, or soy protein. Soy silk looks almost identical to worm silk and can be dyed, blended or spun in the same way. Another similar process is made from milk protein.

These fibers are all factory produced. There is really no way for them to be created at home. But the fiber can be purchased for handspinners or hand dyers to use. Alone or blended with wool or other fibers, rayon is eye and finger candy.

For more about these fibers, see “Rayon, Ingeo, Soy Silk, Bamboo, and More!”

Comments are always welcome here at SlowYarn! Tell us what you think, share your ideas, or comment on the content. Or you can contact me directly at Kelley@SlowYarn.com.

Thanks!

–Kelley

Copyright © 2013 – 2023 Kelley Adams. All rights reserved.

All text, photos, and graphics are the property of Kelley Adams unless credit is given to an alternative source.