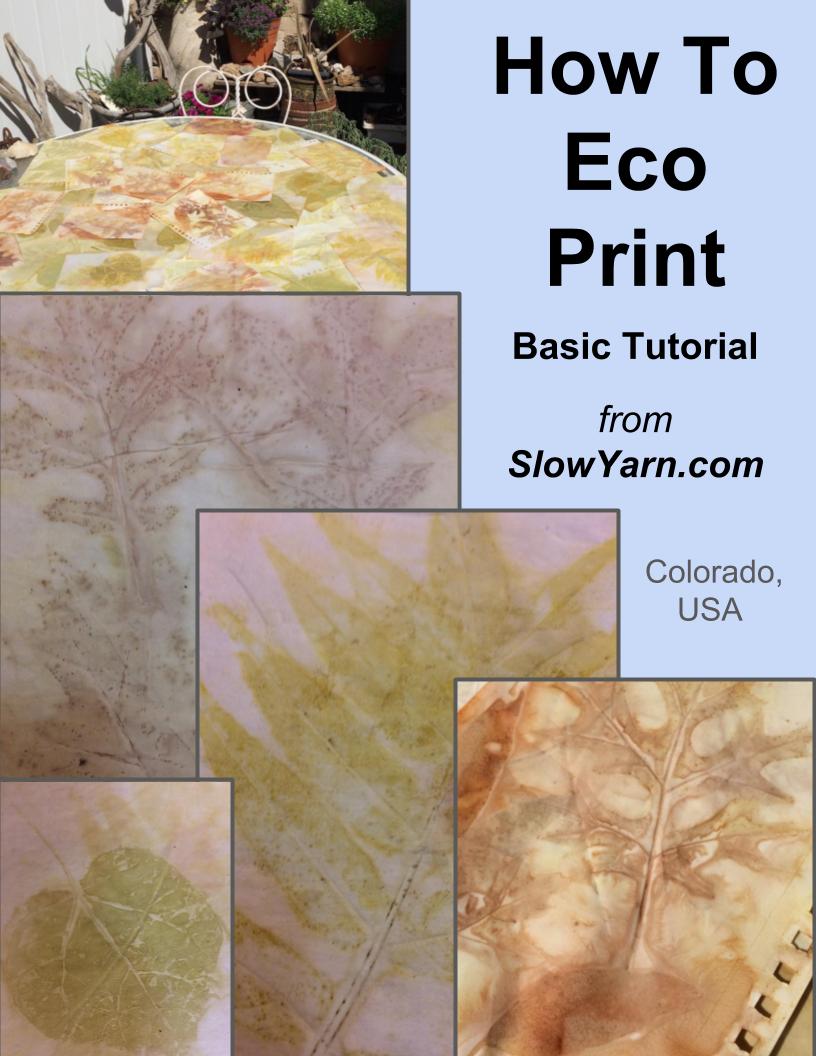

Introduction to Eco Printing

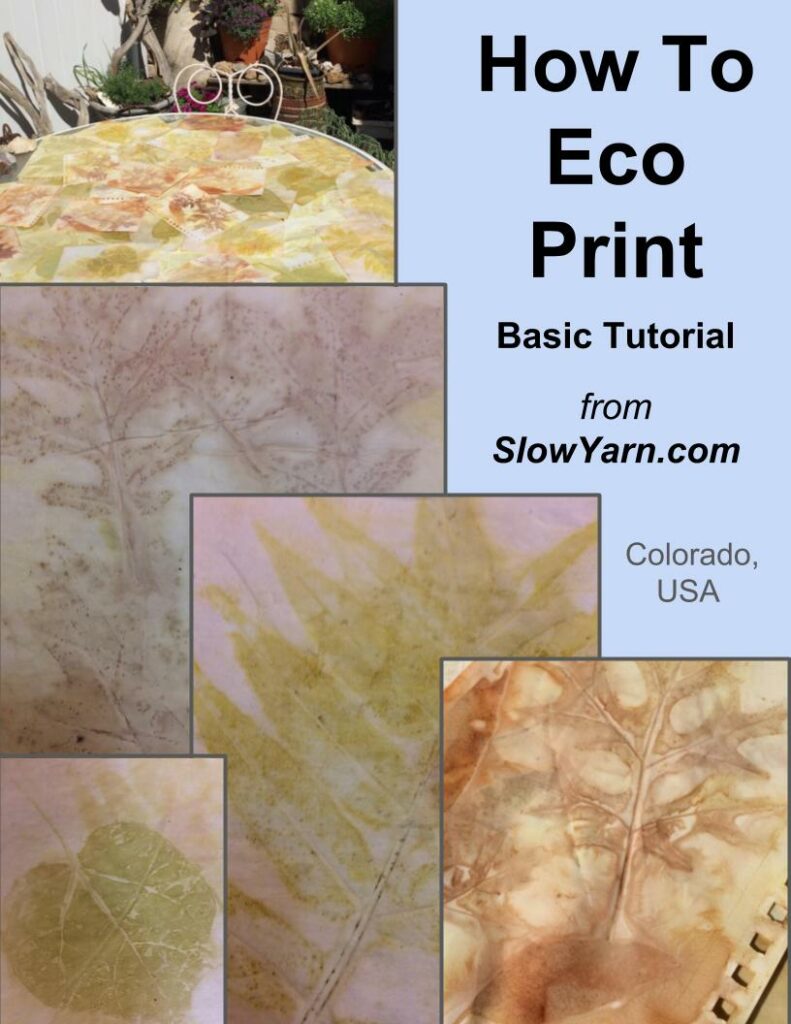

What is eco printing? This is a form of natural dyeing using direct-to-fabric or -paper printing from leaves, stems or flowers. Almost all plants have some color in them that can be transferred directly to the surface of fabric or paper, leaving the impression of the leaf shape on the cloth. Generally, the artist India Flint is given credit for discovering the technique in the mid 1990s, using eucalyptus leaves cooked with bits of iron in the water.

Check here for her iconic book, “Eco Colour: Botanical Dyes for Beautiful Textiles.” It’s eye-candy: a stunning book to look at, even if you never try eco printing.

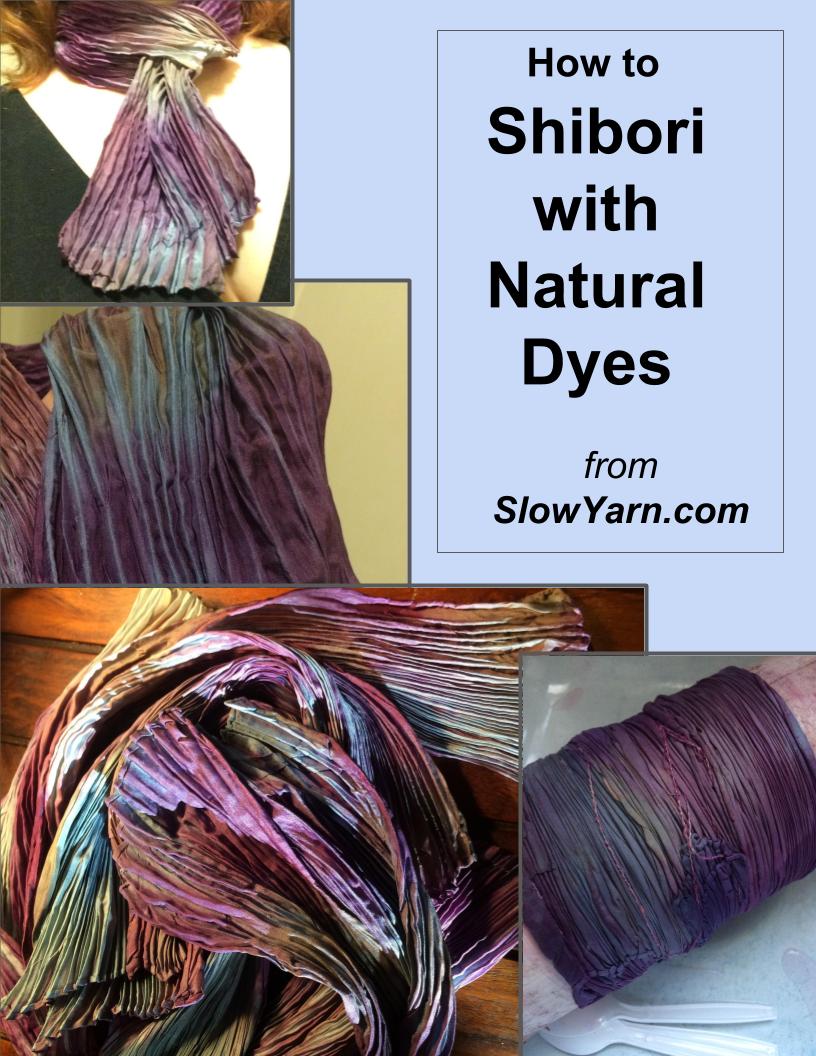

You may have heard of natural dyeing with logwood, madder or even onion skins. Before the mid-1800s, natural dyes were the only source of color on fabric. Most typically, a “tea” was brewed with the plant materials and then strained into a huge pot made with copper or iron. The metals reacted with the “tea,” and left color in the fiber. Dyers would stir constantly to keep the dye even. Not all plants make good dyes, but over the centuries the process of natural dyeing has been refined and shared so that dyers know which are the good plants.

To learn more, click here for “The Modern Natural Dyer,” by Kristine Vejar.

The eucalyptus that India Flint prints with gives an intense dye of bright red-orange. Not all of us have eucalyptus growing in our climate, however! I can tell you from experience that it takes a LOT of maple leaves to dye yarn or fabric to an even color in a pot. But, with the eco printing process, directly pressing the leaves to the fabric, maples will leave beautiful, clear prints. With the addition of iron, either as a solution or as just rusty nails tossed into the dye pot, the natural dye in the leaves reacts more intensely with the fabric.

There are several other metals which change the color or intensity of the prints. These are called “mordants” when used in dyeing. Mordant, from the Latin word meaning “to bite,” opens up the fibers of the fabric or paper to help the dye stay bright with washing and exposure to light over time. There is dispute about whether we can still call the process “eco” when metal salts are introduced, however. Some people prefer to bypass that controversy and refer to the process as “printing with botanicals,” “nature printing,” or simply “printing with leaves.”

There aren’t many differences between nature printing on paper or nature printing on fabric. Prints can be made with no mordants added at all, but pre-mordanting with alum (like the type used to make pickles crisp in the kitchen,) or iron (from rusty metal) can improve the prints and help them be more washfast and lightfast.

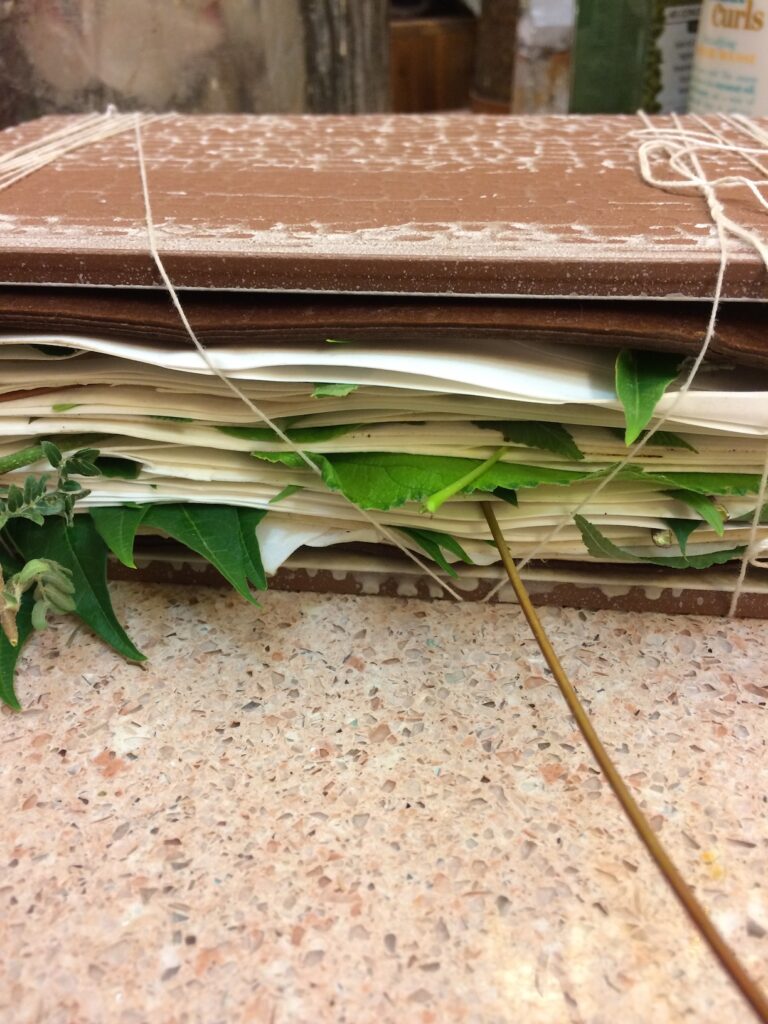

The first time I tried submerging a stack of paper with leaves sandwiched in between each sheet, I thought it was crazy! Paper shouldn’t be underwater! As a stack, however, the paper was fine. I’m sure it couldn’t take much stirring around, but when laid flat it survived 4 hours in the dye pot with no visible deterioration.

When you take it out of the pot and it’s still wet it is a little fragile and prone to tearing, though. Be careful as you separate sheets to pull off the leaves and lay it out to dry. Many people prefer to use only thick, durable watercolor paper, but I’ve had really successful prints on cheap copy machine paper, too, as long as I’m really careful about tearing.

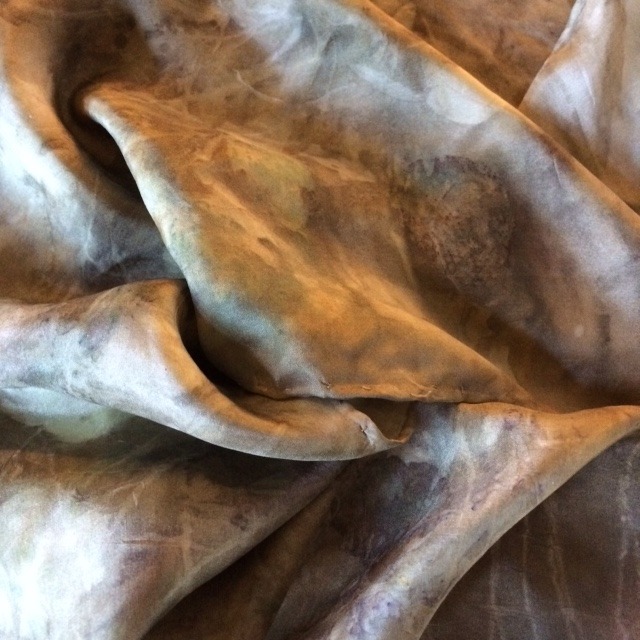

The types of fabric that can be printed should be limited to natural fibers. Man-made fabric from petroleum products refuse to take most dyes available to the home dyer. Cotton, rayon, or bamboo are all great. (Rayon and bamboo are manmade, but they are also natural fibers. If you’d like to learn more, click here to read my article “Rayon, Ingeo, Soysilk, Bamboo and More!” ) Wool fabric takes prints beautifully. Silk becomes the favorite fabric for most eco printers once they try it. Even poor prints without distinct leaf shapes look beautiful on silk, with subtle, mottled natural color.

Not all leaves leave good prints, on any fabric. There is a lot of experimentation in this process, as you learn which of your local leaves work and which don’t. With some, the time of year or the mordant used can make all the difference. With others, they make beautiful silhouette anti-prints, refusing to take any of the color from the dye pot and leaving an unprinted outline. I’ve seen prints made with cottonwood leaves done by other people… but this tree, at my house, has leaves which refuse to print anything more than a faint ghost print:

With some of these non-printers, you can achieve beautiful effects by dyeing the fabric before printing, using a natural dye like cochineal, and the leaf will react with the color and disperse the dye like this elm leaf.

One of the eco printing groups I participate in had a discussion about whether this was an art or a craft. Most of us felt that it is an art form, as the composition of your layout was so individual and that the results always seem to involve some personal magic. Using the same type of leaves, the same mordants, the same fabric, and the same length of time to process, a dozen eco printing artists will each have recognizable styles in their resulting prints. It’s a combination of art and chemistry and… well, magical alchemy; I am endlessly fascinated with the eco printing process.

If you’d like to read more about the process and how it’s done, please go to my tutorial on How to Eco Print.

Comments are always welcome at SlowYarn.com! Let us know if you’ve tried this and what you think!

Copyright © 2018-2020 Kelley Adams. All rights reserved.

All text, photos, and graphics are the property of Kelley Adams unless credit is given to an alternative source.